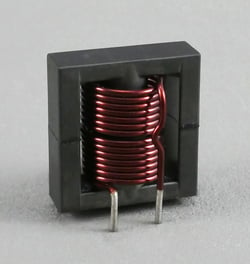

Power inductors can be used to filter the current or convert the Voltage and current to a different Voltage and current. Applications range from small electrical appliances to large power grid systems. Inductors consist of wound conductive metal coils that generate a magnetic field when electricity flows through them. Inductors are essential in any application that needs to carefully control electrical current.

Power Inductor Applications

Inductors have a variety of common applications, such as:

Inductors have a variety of common applications, such as:

- Power Supply Filter: As one of the most straightforward applications for inductors, power supply filters (also known as chokes) must have a high enough level of inductance to keep current from dipping below the circuit’s minimum Voltage requirement at maximum load. The difficulty of calculating the appropriate inductance for power supply filters will vary based on the details of the intended application.

- EMI Filters in AC Inputs: In power supplies and electronic equipment, an EMI filter helps to keep internally generated noise contained within the device in question. Virtually any electrical equipment can function as a source of EMI. The inductive component of an EMI filter behaves as a low-frequency pass device for AC line frequencies.

- Noise Filters: Noise filters are generally used to remove noise spikes from the low frequency AC or DC currents that are entering or leaving your circuit. They smooth these currents.

- Energy Storage in DC-to-DC or AC-to-DC Converters: The input can be DC or a rectified AC signal that has not been filtered. The inductor stores energy in its magnetic field during the time the inductor input current is on. When the input current is turned off this stored energy is transferred to the output of the circuit. This cycle is repeated as needed to maintain the output. This property makes power supply circuits useful for DC-to-DC or AC-to-DC power converters.

How to Select a Custom Power Inductor

When selecting a custom power inductor, there are ten factors to keep in mind based on the intended use and the electrical specifications of the circuit.

When selecting a custom power inductor, there are ten factors to keep in mind based on the intended use and the electrical specifications of the circuit.

- Application and Circuit: Charging inductors will require analysis of the circuit design/schematics, whereas filter inductors are easier to specify and only require identification of the type of circuit.

- Tolerance and Inductance: While off-the-shelf inductors typically allow a 20% inductance tolerance, a custom inductor should feature a lower tolerance of 10% to account for additional design complexity and demanding application variables.

- AC Frequency and Operating Voltage: AC power supply filters operate only at the AC power switching frequency, while other applications may vary more widely.

- DC Current: Determine the size of the DC current range required by the coil to ensure proper coil selection.

- DC Resistance (DCR): While not all inductors require DCR, any inductor that must operate at or near frequencies of 0 Hz (or if tolerances overlap 0 Hz) will need appropriate specification.

- Max Working Voltage and/or Dielectric Strength: Review application requirements to understand the maximum allowed Voltage of the inductor before dielectric breakdown will occur.

- Case Type: Establish the size and dimensions of the case to ensure the inductor will work within the design.

- Terminals: Take any associated terminals into account, like wire leads, turrets, lugs and more.

- Environmental Requirements: The conditions of the operating environment, such as ambient temperatures, humidity levels, altitude levels, and various other properties will help to specify the appropriate power inductor.

- Industry/Application Specifications: Power inductors are not universal. Select an inductor approved for use in the specific commercial, industrial, or military application of your industry.

Custom Designs Are Made Easy Through Triad's US Design Center

At Triad Magnetics, we've been offering premium magnetics solutions for more than 75 years. We offer more than 1,000 standard part designs in conjunction with advanced customization capabilities. For more information about specifying custom power inductors or any of our other solutions, please don’t hesitate to contact us today or download our eBook, Guide to Inductors.

.png?width=220&name=info.triadmagnetics.comhs-fshubfsGuide%20to%20Inductors%20(1).png)