A choke is a magnetic inductor used to block or limit unwanted high-frequency alternating current (AC) while allowing the desired lower frequency direct current (DC) to pass through. The choke acts as a filter for the noise produced by other radio signaling devices, inverters, and unshielded equipment, thereby reducing interference in electrical and electronic devices and systems.

Common mode chokes are capable of filtering two or more lines of current at the same time through the use of one common magnetic core. They are typically available in two classes: radio frequency (RF) and audio frequency (AF) chokes. The primary difference between the two is the composition of the choke’s core. RF chokes use a magnetic core made of powdered iron or ferrous beads with complex coil winding patterns to filter out noise frequencies, while AF chokes are composed of a solid magnetic iron core.

Common mode chokes find use in a wide range of industrial applications. They are especially useful for the suppression of noise and current fluctuation in operations with large current flows, such as AC/DC power supply lines and video signal lines. The following blog post outlines some of the applications of common mode chokes and key considerations to keep in mind when choosing one for a particular use case.

Applications of Common Mode Chokes

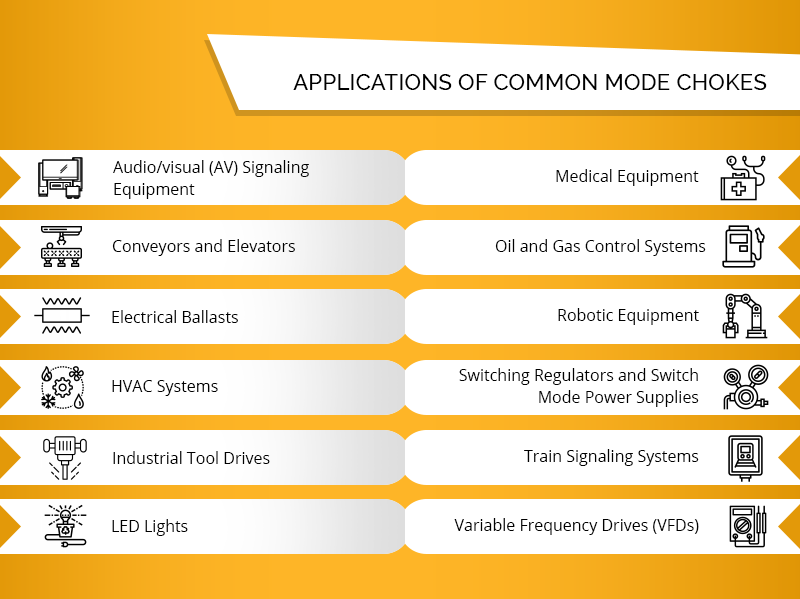

Common mode chokes are typically used to mitigate or eliminate electromagnetic interference (EMI) in industrial applications that require a steady and reliable current without interruption. Typical electrical and electronic devices that may use common mode chokes include:

- Audio/visual (AV) signaling equipment

- Conveyors and elevators

- Electrical ballasts

- HVAC systems

- Industrial tool drives

- LED lights

- Medical equipment

- Oil and gas control systems

- Robotic equipment

- Switching regulators and switch mode power supplies

- Train signaling systems

- Variable frequency drives (VFDs)

Selection Considerations for Common Mode Chokes

When selecting a common mode choke for a given application, it is important to consider the specific requirements and restrictions of the system for which it is being installed. Common mode chokes are manufactured in a wide range of sizes and designs to suit a variety of use cases. As a general rule, larger chokes are capable of filtering lower frequencies than smaller chokes, making them suitable for equipment that requires more accurate noise filtering, such as AC/DC outlets.

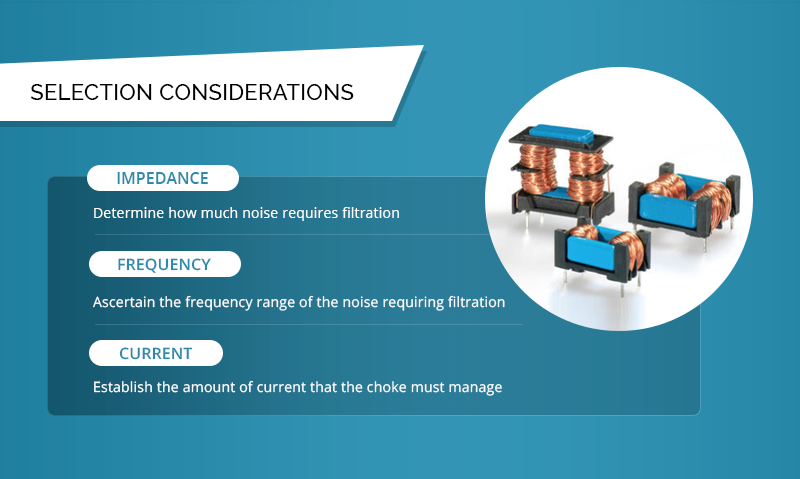

Three key factors to consider when selecting a choke are:

- Impedance: determine how much noise requires filtration

- Frequency: ascertain the frequency range of the noise requiring filtration

- Current: establish the amount of current that the choke must manage

In addition to these considerations, it is also essential to choose a choke that maintains the quality of the signal. An ideal choke should demonstrate compatibility between its impedance characteristics and the transmission line, resulting in little to no influence over the signal quality after insertion.

Standard Chokes From Triad Magnetics

At Triad Magnetics, we offer a broad selection of standard choke and inductor products for use in a diverse set of industrial applications. Our product offerings include:

- CMF series common mode inductors

- CMT8100 series common mode inductors

- CMT908 series common mode inductors

- CME series common mode inductors

- UT/ET series common mode inductors

- Switch mode/high-frequency differential mode toroidal inductors

- Switch mode/high-frequency rod core inductors

- AX97 series SMD power shielded inductors

- AX104R series SMD power shielded inductors

- AX1005 - 102K series SMD power shielded inductors

- AX02 series SMD power shielded inductors

- Smoothing filter chokes

Custom Chokes and Inductors From Triad Magnetics

Our ISO 9001:2015 certified US Design Center provides one-stop custom design services, ranging from the initial design to precision prototyping to extensive testing. By partnering with us for their choke or inductor needs, customers can benefit from our:

- Highly skilled engineering team that can fabricate and modify custom inductors and chokes for any application

- Design expertise with magnetic core materials such as amorphous alloys, ferrites, iron powders, and laminations, as well as conductor materials such as magnetic wire, Litz wire, and copper or aluminum foil

- In-process quality inspection protocols that ensure all of our products are held to the most rigorous standards in the industry

- Worldwide network of manufacturing facilities that provide reliable and timely delivery of superior products

Our team works closely with each customer to understand individual mechanical and electrical requirements, creating the ideal custom solution for any product design challenge.

For more information on our inductors and chokes, contact us today. We look forward to helping you to select the best products for your unique application.