Our engineering team frequently receives questions about whether we use Litz wire in our designs. We decided to focus this blog on educating our clients on this subject and explain why Litz wire is so ideal for certain applications and industries. Using Litz wire is associated with a number of benefits, including:

- Decreased occurrences of “hot spots”

- Reduction of AC power loss

- Minimized eddy current losses

The term “Litz wire” originated from a German word meaning woven wire:  litzendraht. Litz wire is comprised of magnetic wires that are individually insulated before being twisted (or braided) into a uniform pattern. Winding these wires together reduces field resistance, which, in turn, allows electric currents to flow more freely.

litzendraht. Litz wire is comprised of magnetic wires that are individually insulated before being twisted (or braided) into a uniform pattern. Winding these wires together reduces field resistance, which, in turn, allows electric currents to flow more freely.

Litz wire is regularly used in projects in a sizable variety of industries, including the aerospace, communications, medical, and green energy sectors.

What Is Litz Wire?

Litz Wire Sizes

Litz wire comes in a number of sizes, which are often expressed in an abbreviated format, as follows: N/XX, where

- N indicates the number of strands

- XX refers to the American Wire Gauge (or AWG) size of each strand

In a typical application, this translates to a format that may appear as “25/40.” These numbers tell industry professionals that there are 25 strands of 40 AWG.

Often, following sizing information, there are further details concerning insulation and serving or jacketing options. The type of wire used plays a crucial role in the selection process and should be scrutinized carefully before purchasing.

Different Kinds of Litz Wire

Litz wire is available in eight commonly recognized varieties. They range from single-twist wires to complex bundles formed into specialized shapes or outfitted with specialized cores. The types are:

- Type 1 Litz wire

- Basic single twist

- Elective external insulation

- Type 2 Litz wire

- Twisted bundle of Type 1 wire woven together

- Can have external insulation

- Type 3 Litz wire

- Pre-insulated bundles of Type 2 wire

- Woven together with a choice to have external insulation around the full bundle

- Type 4 Litz wire

- Fiber core at the center of twisted bundles of non-insulated Type 2 wire

- Type 5 Litz wire

- A combination of bundles of insulated Type 2 wire that has a fiber core

- Type 6 Litz wire

- Bundles of Type 4 wire outfitted with a fiber core

- Type 7 Litz wire

- Braided insulated wire in the form of a rectangle

- Type 8 Litz wire

- Single-twisted insulated strands compressed into a rectangular shape

Litz Wire Applications

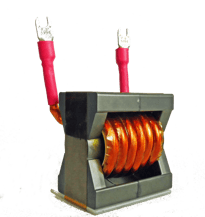

Litz wire is beneficial in a multitude of applications that span across a range of industries. It’s an ideal solution for high-frequency applications thanks to its ability to improve the efficiency of critical machinery and components like transformers, inductors, and coils. Comparable alternatives, like those made of standard copper wire, are generally unable to allow for maximum efficiency during operation due to increased resistance and current loss.

Whether you work in a factory or out in the field, there’s a high likelihood that some part of your day-to-day duties puts you in closer contact with Litz wire than you’d anticipate. Some common applications include:

- Antennas

- High-frequency power converters

- Grounding

- Electromagnetic induction (or heating)

- Chargers for medical devices

- Radio transmitters

- Sensor wiring

- Wireless power systems

- Acoustic telemetry (also known as sonar)

- Ultrasonic devices

- Wind turbines

- Wire coils

- Hybrid vehicles

- Chokes (or high-frequency inductors)

- Electric chargers for motor vehicle applications

- Motors, including:

- Linear motors

- Stator windings

- Generators

- Transformers

- Communications

- Radio

- Transmission

Contact Triad Magnetics for Our Exceptional Litz Wire Products

At Triad, we rely on Litz wire for custom designs where high frequency, high power transformers are required. Our team has over twenty years of experience in the magnetics business and is ISO9001 and AS9100:2016 compliant, so you can rest assured that the products you receive are held to the utmost standards.

In our next blog, we’ll delve into the benefits of utilizing Litz wire versus copper foil in custom designs.

If you’re interested in learning more about using Litz wire in your next project, get in touch with us and request a quote today!